Annex A

2017-10-13

World’s first index to help companies embark on Industry 4.0 transformation

Singapore, November 13, 2017 – Singapore Economic Development Board (EDB), in partnership with global testing, inspection, certification and training company TÜV SÜD, launched a world-first tool – The Singapore Smart Industry Readiness Index – to help industrial companies harness the potential of Industry 4.0 in a systematic and comprehensive way.

(From left) Mr Lim Kok Kiang, Assistant Managing Director, EDB; Mr Chng Kai Fong, Managing Director, EDB; Dr Andreas Hauser, Director of Digital Services, TÜV SÜD; Mr Jackie Tan, Senior Consultant, TÜV SÜD at the launch of the Index in November 2017

The Index serves as a diagnostic tool that companies - across all industries and sizes - can use to better understand Industry 4.0 concepts, evaluate the current state of their facilities, architect a comprehensive transformation roadmap and deliver concrete, sustained value for their businesses.

EDB’s Assistant Managing Director Lim Kok Kiang said, “As part of our efforts to enhance the competitiveness of Singapore’s manufacturing sectors, the Index provides a common framework for all companies to participate in, and benefit from, Industry 4.0.”

He added, “Many companies often put technology first. With this Index, we put people and processes alongside technology, so that companies can maximise the potential of Industry 4.0.”

Prof Dr –Ing Axel Stepken, Chairman of the Board of Management, TÜV SÜD described the Index as a world-first for the industry.

“The Index gives clear orientation to manufacturers on what Industry 4.0 means and how they can initiate their transformation journey. It is a world’s first Industry 4.0 tool that is developed by the government for nation-wide transformation of industrial sectors. Strongly aligned with Industry 4.0 and other global manufacturing initiatives, it has the potential to be the global standard for the future of manufacturing,” he said.

The Index draws reference from the RAMI 4.0 framework1 and was validated by an advisory panel of 21 academic and industry experts. To strike a balance between technical rigour and usability, the Index was piloted with both small medium enterprises (SMEs) and multinational corporations (MNCs) in Singapore. The Index also received the support of Singapore Government agencies. (See Annex A for details of partners and the advisory panel)

1 Reference Architectural Model for Industry 4.0 (“RAMI 4.0”), which was developed by Plattform Industrie 4.0. Today, RAMI 4.0 has been formally acknowledged by key experts and renowned associations globally to be the reference architecture model as it embodies the key concepts and ethos of Industry 4.0

“While the term Industry 4.0 was created several years ago, many manufacturing companies, particularly SMEs, remain unfamiliar with it,” said Mr Desmond Goh, Director of food manufacturing SME, People Bee Hoon, “This Index is an intuitive and realistic reference framework which is useful for all industrial companies, both big and small, to not only learn these new concepts but also to apply them to our facilities.”

The Index: ensuring no aspects are overlooked

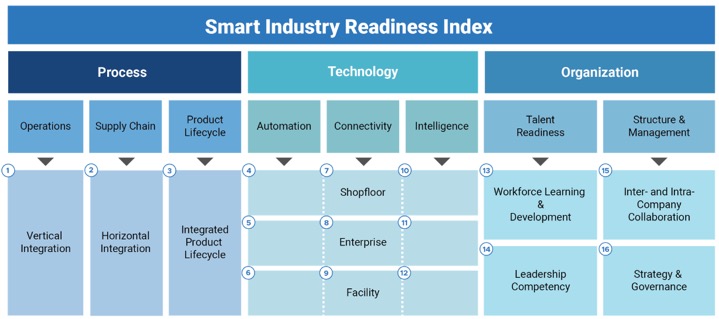

The Index comprises three layers. At the top are the 3 fundamental building blocks of Industry 4.0: Process, Technology and Organization. Underpinning these building blocks are 8 pillars of focus. These pillars then map onto 16 dimensions of assessment, which represent the key components that any organization must consider.

For each of the 16 dimensions, the Index provides an assessment matrix which companies can use to evaluate their current processes, systems, and structures within one to two days. The assessment matrix also doubles as a step-by-step improvement guide, as each dimension provides intermediate steps needed for companies to progress.

To Mr Yeoh Pit Wee, Director for Manufacturing Operations, Rockwell Automation, the Index helps companies perform a comprehensive evaluation of their facilities.

“Often, companies tend to focus excessively on shop floor automation and under-invest in equally important areas such as process design and workforce competency. The Index serves as a useful counter-check to ensure that no dimensions are overlooked, in order to capture maximum value from any Industry 4.0 initiatives,” he said.

Mr Hashim Baba, Plant Manager, Becton Dickinson Singapore added, “The Index allows our manufacturing team to take stock of what we are doing well and where we can do better. This forms a good basis to build a shared Industry 4.0 vision and strategy, enabling us to take decisive action in initiating a multi-year transformation journey.”

Annex A

2017-10-13