The manufacturing sector is a key pillar of Singapore’s economy. It contributes about 21%, or $106 billion of the country’s total Gross Domestic Product, and employs close to half a million workers.

Globally, manufacturing is changing. Through digitalisation and automation, manufacturing in the age of Industry 4.0 will become smarter and more advanced. For Singapore to maintain its competitive edge, it needs to be agile and adapt accordingly.

Which is why Manufacturing 2030, a 10-year roadmap to further grow the sector by 50%, is in motion. It emphasises the importance of the sector, what with some sub-sectors, such as biomedical electronics and precision engineering, becoming “bright spots” of the economy during the COVID-19 pandemic.

“Beyond the 50% increase in value, we want to see a greater proportion of our manufacturing going into advanced manufacturing, where the competition is not based on cost but based on the intellectual property that we can generate, the quality of the products and the precision that we can provide for the sector,” said Minister for Trade and Industry Mr Chan Chun Sing.

In addition to government measures that attract world-renowned players to anchor their operations in Singapore, efforts to nurture the advanced manufacturing capabilities of local companies will also be increased as part of the plan.

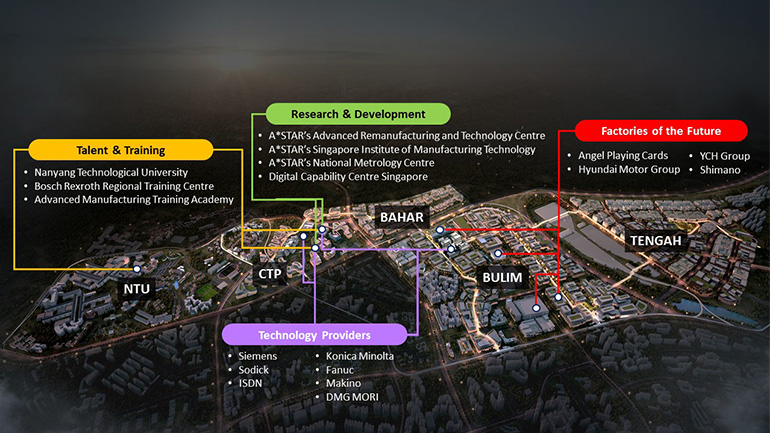

Spread over 600 hectares, Jurong Innovation District (JID) is where the action will take place. Here are five things to know about the advanced manufacturing hub that will fuel the growth of Singapore’s industries:

A vibrant ecosystem awaits at this one-stop hub

The advanced manufacturing value chain looks set to thrive at JID, thanks to an ecosystem that spurs innovation. Research institutes, training providers, technology experts and advanced manufacturers are in one convenient spot, making collaborations that much easier.