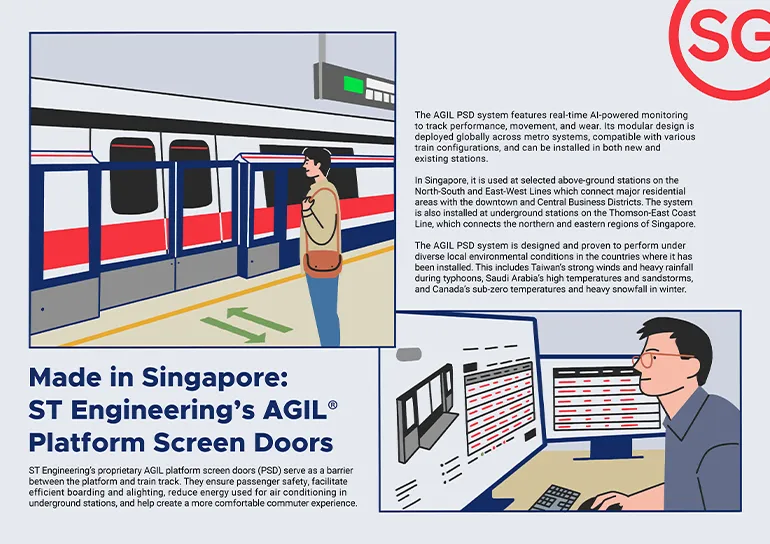

The morning commute, made safer

ST Engineering – AGIL® Platform Screen Door system

ST Engineering’s AGIL Platform Screen Door (PSD) system is a modular safety barrier system that can be installed along elevated, at-grade, and underground station platforms. It prevents commuters from accidentally stepping onto the tracks by remaining closed until the train has fully arrived, and opens only when the train’s doors are aligned.

The PSD system is compatible with various train configurations and car lengths, and suitable for installations in new stations or retrofits in existing stations. It can be customised with a range of materials, colours, and finishes to match the station’s aesthetics. The system also provides sound and thermal insulation to enhance a more pleasant platform environment, helping to buffer the noise and air drafts that would otherwise affect commuters each time trains enter the station. It also includes smart features such as real-time diagnostics, passenger-counting, and digital displays, enabling rail operators to monitor crowd flow and equipment conditions more effectively. Additionally, the AGIL PSD system is equipped with an intelligent monitoring system that uses artificial intelligence (AI) to track door movement, motor performance, and wear indicators, allowing for more precise and predictive maintenance. These capabilities help improve service reliability.

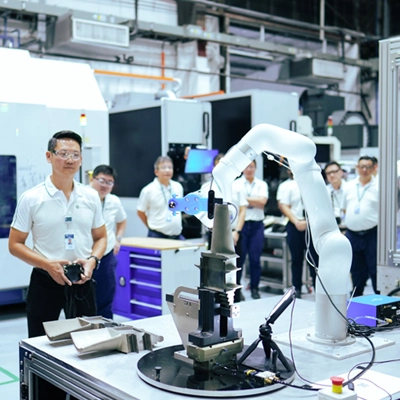

ST Engineering’s PSD capability is driven by its Urban Solutions business area at its Singapore headquarters. Its team of engineers, designers, and technicians have diverse expertise in mechanical, electrical, electronics, and software engineering, as well as system integration, functional safety, and AI analytics. Being based in Singapore gives the team access to a strong talent pool and allows much of the development work – design, prototyping, testing, and refinement – to be done locally. This enables fast turnaround, tight quality control, and closer collaboration between engineering disciplines.

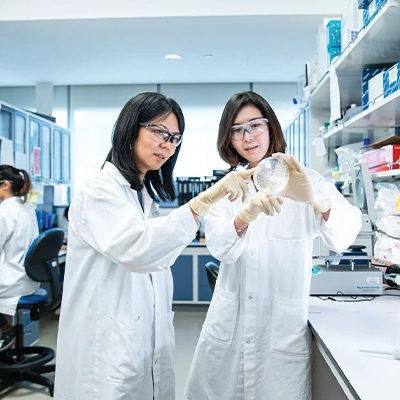

In addition to harnessing AI for new innovations, ST Engineering is also advancing agentic AI and equipping the next generation of cybersecurity talent to thrive in AI-assisted cybersecurity environments. Led by its Cyber business, the company’s newly established Cybersecurity Centre of Excellence (CoE) aims to accelerate the development of agentic AI-driven cybersecurity solutions. The CoE will enhance cyber defence across enterprise information technology (IT) systems, fifth-generation (5G) mobile networks, and operational technology/Internet of Things (OT/IoT) systems, which will address the future wave of advanced threats.

Partnerships with Singapore’s government agencies have also supported ST Engineering’s global and regional growth, through connections to suppliers, installation contractors, and system integrators. Together, these strengths have helped transform the AGIL PSD system from a locally engineered solution into a globally recognised platform, now used in modern metro networks around the world – including Canada, Saudi Arabia, Taiwan, and Thailand.