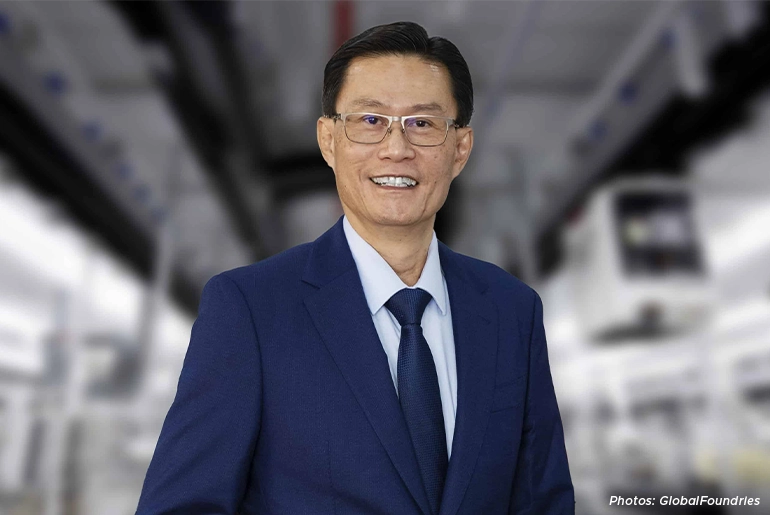

GlobalFoundries is taking a big step towards greener chipmaking with a breakthrough initiative at its Singapore site.

Its 200 mm fab Remote Plasma Clean project replaces traditional chamber-cleaning processes, which were among the company’s largest contributors to Scope 1 emissions in wafer fabrication, with a more environmentally efficient alternative.

By switching to an alternative reaction gas and optimising the recipe and equipment, the upgraded processes achieved a 97 per cent reduction in carbon emissions, eliminating more than 46,000 tonnes of carbon dioxide equivalent annually.

Through careful phased implementation, GlobalFoundries successfully managed the inherent risks of introducing new technology to sensitive semiconductor manufacturing processes. The successful deployment in phase one enabled the rapid roll-out of subsequent phases in other processes within the company’s 200 mm fab in Singapore.