- Engineered for extremes: TechnipFMC’s high-tech components enable safe and efficient energy production

- Connecting Singapore to the world: Maersk's end-to-end supply chain solutions for goods from healthcare to luxury fashion

- Shaping Singapore’s skyline and shoreline: Obayashi celebrates 60 years of engineering

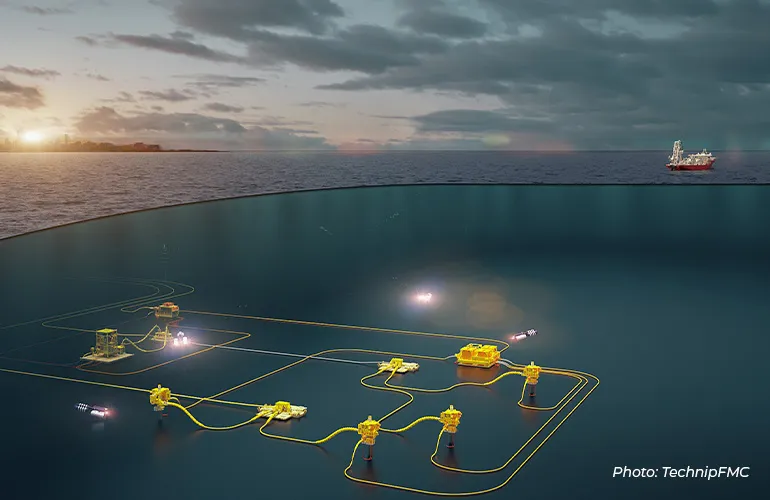

Engineered for extremes: TechnipFMC’s high-tech components enable safe and efficient energy production

TechnipFMC is a leading technology supplier to traditional and new energy industries. It has its engineering and manufacturing facility for APAC in Singapore, and its products made here include Subsea pressure-containing equipment, designed to operate under extreme conditions.

Deep beneath the ocean, where crushing pressures and extreme temperatures challenge even the toughest materials, TechnipFMC’s components keep performing. Pressure-controlling valve blocks and tubing hangers created in Singapore form vital connections in subsea and surface operations worldwide, ensuring safe energy production.

TechnipFMC established its Singapore manufacturing hub in 1975 to serve regional customers, attracted by Singapore’s strategic location, developing manufacturing sector, and skilled workforce. Initially focused on production, the facility has since become TechnipFMC’s global production site for subsea core products, as well as a leader in innovation.

The Singapore hub employs best-in-class technologies and automation. Digital transformation partnerships with TÜV SÜD and McKinsey launched since 2017 have set a solid foundation for transformation and growth. The Singapore hub continues to learn and apply industry best practices, while driving continuous improvement in precision manufacturing. The company has also developed Singaporean leadership across operations, finance, and engineering.

Meet the Singaporeans: Alex, Roselind, and Jiaming

Swipe to read about TechnipFMC’s past 50 years in Singapore:

Connecting Singapore to the world: Maersk' end-to-end supply chain solutions for goods from healthcare to luxury fashion

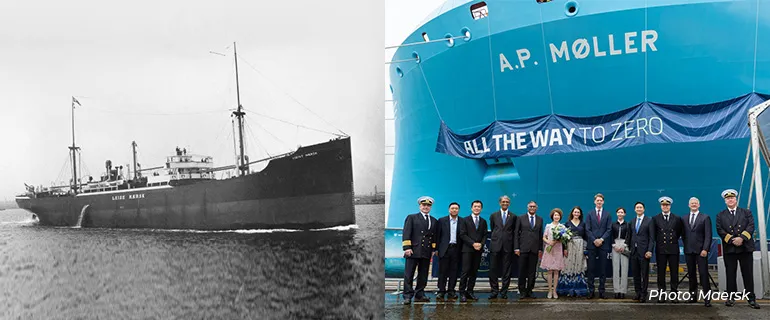

(Left) Leise Maersk, the first Maersk ship to call at the Singapore port in 1929; (Right) Ship naming of A.P. Møller in 2024

Leise Maersk was the first Maersk ship to call at the Singapore port in 1929 but it was not until 1975 that the Danish integrated logistics company Maersk opened its first office here to grow its container shipping business. The company was betting on Singapore’s strategic position among major trade lanes and 50 years later, the bet has paid off. Singapore now serves as Maersk’s regional headquarters with around 1,500 employees – triple the workforce from just five years ago.

“Singapore’s strategic location among major trade lanes and its position as one of the busiest ports in the world” were key attractions, says Ditlev Blicher, President, Asia Pacific at Maersk. Singapore’s stability, pro-business environment, and diverse talent pool continue driving Maersk’s growth. The company’s Singapore-registered fleet has more than doubled compared to a decade ago, with approximately 40 vessel calls weekly connecting the Singapore port to Maersk’s intra-Asia, East-West, and North-South networks.

Over the years, Maersk has gone beyond just ocean shipping to providing a complete logistics ecosystem – offering customers end-to-end supply chain solutions, including warehousing, multi-modal transportation, and last-mile delivery. Changi airport serves as Maersk’s ASEAN air freight hub, while the upcoming World Gateway 2 regional distribution centre – a 1.1 million square feet facility in Jurong West – will cater to the booming e-commerce and logistics needs across industries from healthcare to luxury fashion.

Singapore’s net-zero ambitions are also aligned with Maersk’s commitment to sustainability. In July 2023, Maersk conducted the world’s first ship-to-container-ship methanol bunkering operation here, in partnership with Hong Lam Marine Pte Ltd and with the support of the Maritime and Port Authority of Singapore. It also named one of its latest dual-fuel methanol container vessels, A.P. Møller, in Singapore in November 2024.

Meet the Singaporean: Lim Wen Bing

At Maersk, Lim Wen Bing heads the team focusing on one of the world’s largest trades: the intra-Asia trade. It represents over half of all Asian commerce1. Wen Bing has been with Maersk for 18 years, progressing from designing ocean service networks and partnering terminals, to now heading strategies that connect manufacturers, businesses, and consumers across the region.

Maersk has increased capacity deployed on this trade in response to customers’ growing demand, and Wen Bing and her team continue to find ways to support customers as they grow their trading activities within the region.

Read Carrie Yap’s story on how she went from cabin crew to overseeing regional air freight operations at Maersk

Shaping Singapore’s skyline and shoreline: Obayashi celebrates 60 years of engineering

What do Tokyo Skytree and Jewel Changi Airport have in common? Both were constructed by Obayashi Corporation, one of Japan’s largest construction companies and Singapore’s oldest international builders.

Obayashi first established its Singapore office in 1965. One of the company’s first major projects was the East Coast Reclamation, which added 1,114 hectares (that’s more than 10 times the size of Gardens by the Bay today!) to Singapore’s landmass. Since then, Obayashi has built landmark structures, including Jewel Changi Airport, Mandai Bird Paradise, Funan Mall, and DUO. Obayashi also played a part in building MRT stations on the East-West and North-East Line, including Bedok and Dhoby Ghaut.

Beyond construction, however, Singapore has become the site of Obayashi’s innovation engine for Asia. In 2024, the company established the Obayashi Construction-Tech Lab Singapore (OCLS), the first of its kind in the region, in Singapore. OCLS pioneers next-gen construction technologies, using robotics, automation, and 3D printing to address challenges like labour shortages and productivity demands.

With the Skyjuster and Remote Crane, supervisors can plan and activate the hoisting remotely. The system calculates the most efficient route for lifting and transporting, while the SkyJuster facilitates precise orienteering and aligning suspended components with minimal sway.

The OCLS collaborates with universities, startups, and research institutions across Asia to develop and field-test solutions. Singapore’s research ecosystem, pro-innovation policies, and position as a regional hub make it the ideal base for testing technologies that will shape construction across Asia.

Meet the Singaporean: Patrick Chia

Patrick (top right in black shirt) and his team

At Mandai Bird Paradise – one of Singapore’s latest attractions – 49-year-old Patrick Chia led the integration of digital construction software that improved clash detection, coordination efficiency, and ensured installation accuracy in a complex, thematic development. Patrick, a senior general manager, started his journey at Obayashi in 2000 as a fresh graduate. Over the years, he rose through the ranks and today oversees multidisciplinary project teams.

Grow and scale your business from Singapore

Singapore offers a business-friendly environment, diverse pool of skilled talent, and strong connectivity to the region and the world. Find out all you need to know in our Guide to Setting Up in Singapore.

Global companies like HP Inc, Accenture, Festo, are among the companies that marked growth milestones in Singapore in 2025. Read their stories here.

Footnote:

1 https://www.imf.org/en/news/articles/2025/03/05/sp030525-md-asias-next-growth-frontier