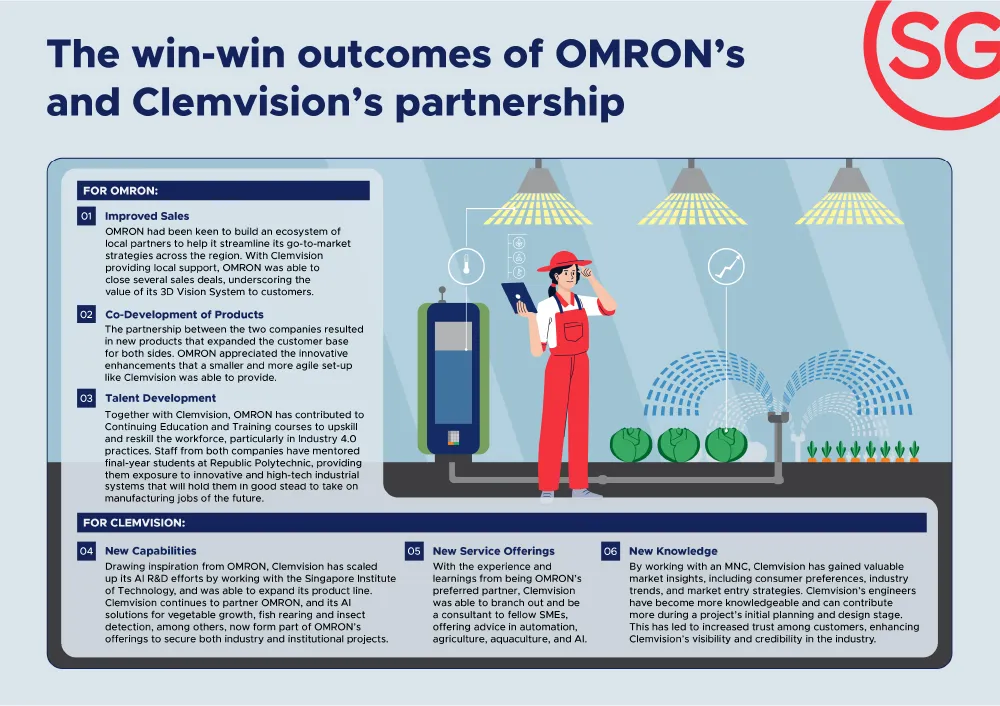

Home to several thousand MNCs and 286,000 small and medium-sized enterprises (SMEs), Singapore offers a rich business ecosystem where leading companies and local enterprises collaborate for mutually beneficial outcomes.

Local enterprises can tap into MNCs’ significant resources and global expertise to innovate and develop new capabilities. For MNCs, partnering with local businesses helps them tailor solutions that cater to business and consumer needs that are unique to Asian markets. MNCs are also able to build a network of local suppliers as a hedge against supply chain disruptions, high freight costs, and import costs.

Here are three collaborations between MNCs and local enterprises that have achieved win-win outcomes.

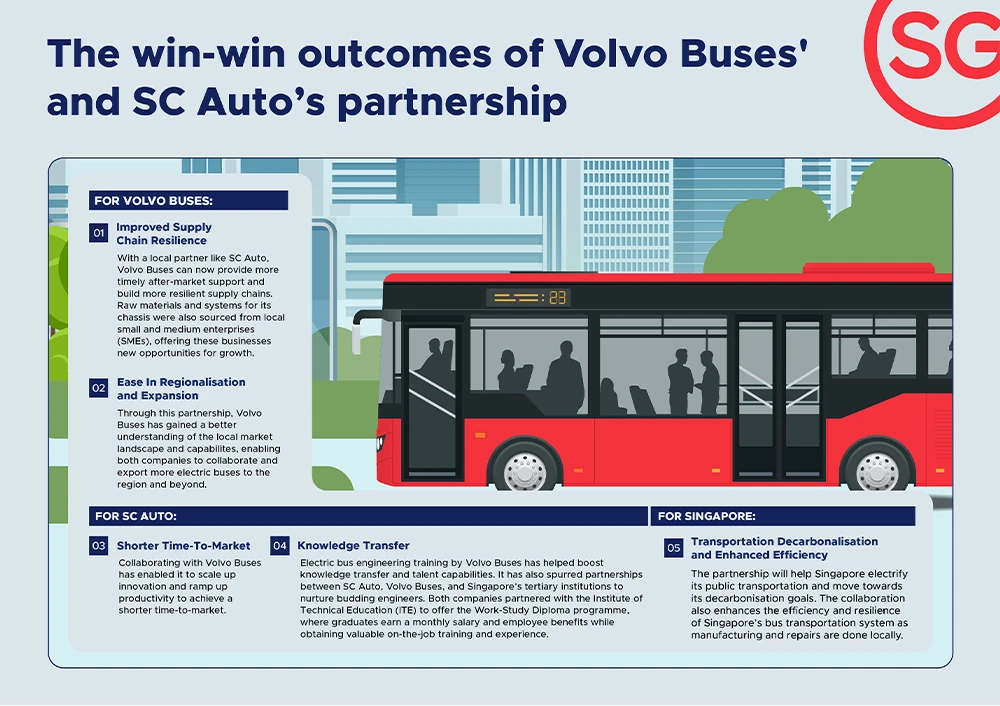

Volvo Buses and SC Auto: Greening Singapore with the first made-in-Singapore electric bus

THE PARTNERSHIP

For over a decade, Singapore's SC Auto Industries (SC Auto), a designer and manufacturer of buses and trucks, and Swedish commercial vehicle manufacturer, Volvo Buses, have collaborated on various projects, including the production of buses on a Volvo chassis. Now, their shared expertise has led to their latest achievement: the first made-in-Singapore electric bus model.

Using more electric vehicles supports Singapore’s overarching goal of cutting land transport emissions by 80 per cent by around 2050. Demand for low-emissions transport is expected to rise globally, given that the transport sector accounts for a fifth of global emissions. By 2030, at least one in two public buses in Singapore — which has a population of close to six million — will be electric, bringing the total number of battery-powered buses to about 3,000.