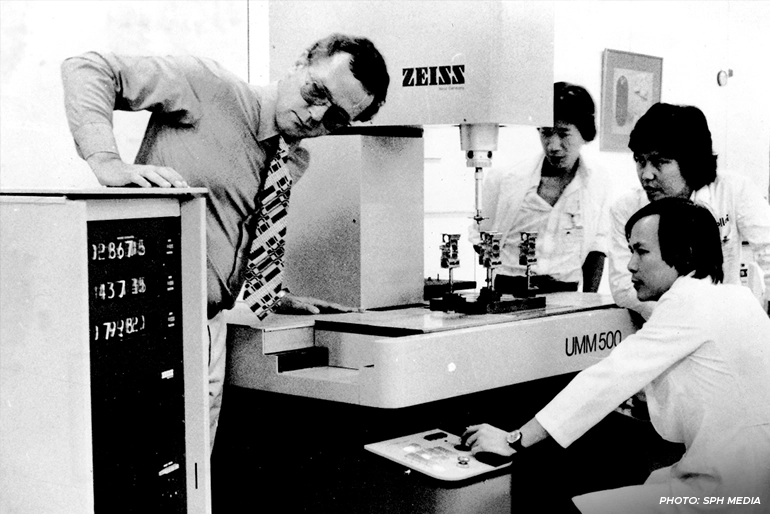

In 1965, newly independent Singapore had no natural resources, hinterland, or industrial base. But over six decades, it became a global hub for high-tech manufacturing.

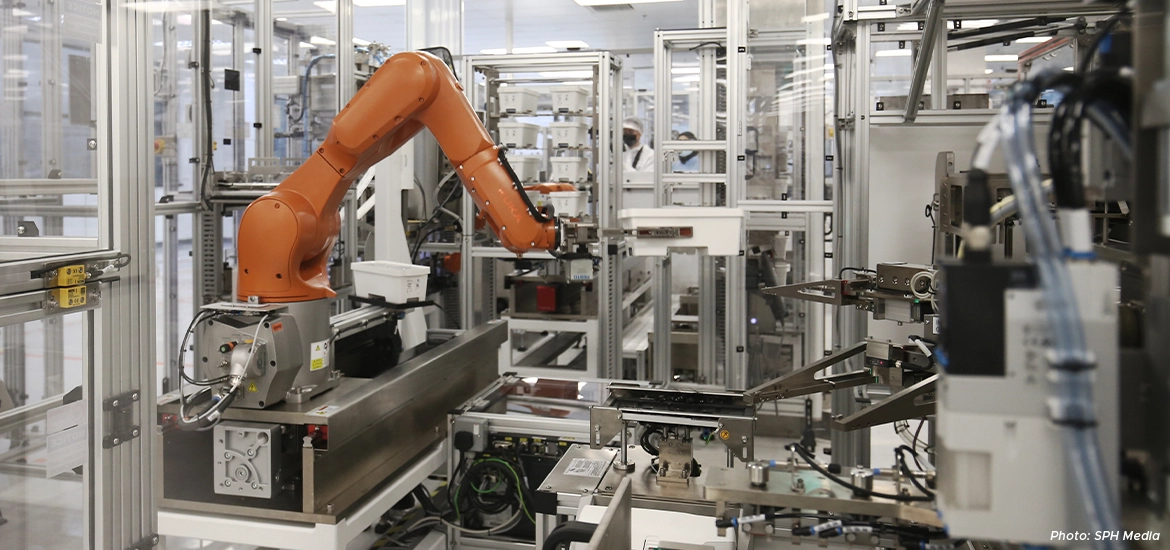

Today, manufacturing remains a key economic pillar, accounting for over 17 per cent of gross domestic product.

The Republic has left some products behind, but is moving up the value chain for others, such as semiconductors. The Business Times traces this evolution.