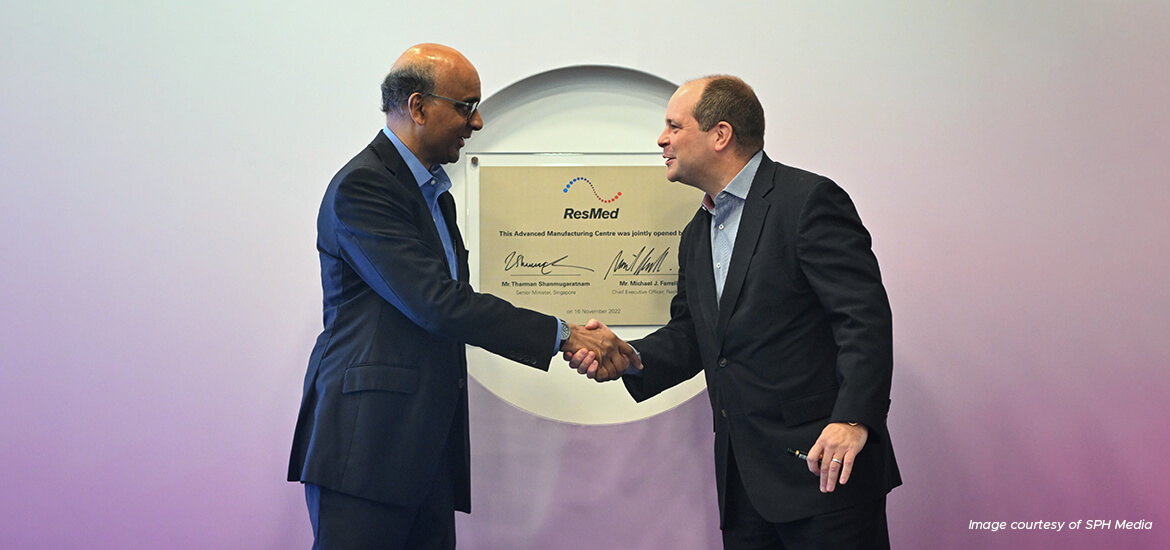

Senior Minister Tharman Shanmugaratnam (left) and ResMed CEO Michael Farrell opening the ResMed Advanced Manufacturing Centre on Nov 16, 2022.

Global medical technology company ResMed officially opened its largest advanced manufacturing centre on Wednesday.

ResMed, a California-headquartered company, pioneered the use of positive airway pressure to treat sleep-disordered breathing in 1989.

Products manufactured in the Tuas facility will reach over 250 million people globally each year by 2025, and will represent a significant proportion of Singapore's medtech exports to the world.

The four-storey 270,000 sq ft facility - almost the size of five football fields - produces devices and systems primarily aimed at tackling sleep apnea, a condition where breathing stops and restarts many times while a person is asleep.

An estimated 936 million people, including nearly 2.3 million in Singapore, have sleep apnea, according to medical journal Lancet Respiratory Medicine.

Another 810 million people suffer from pulmonary-related complications.

As one-third of a person's life is spent sleeping, the amount of impacted rest-hours is a huge burden on public health.

Some 900 staff, including design engineers and research engineers, currently work in this new facility, which began operations in March.

It is ResMed's first such facility here. It has similar facilities in countries such as Australia and the United States, supplying products to some 140 countries.