Electronics manufacturing services

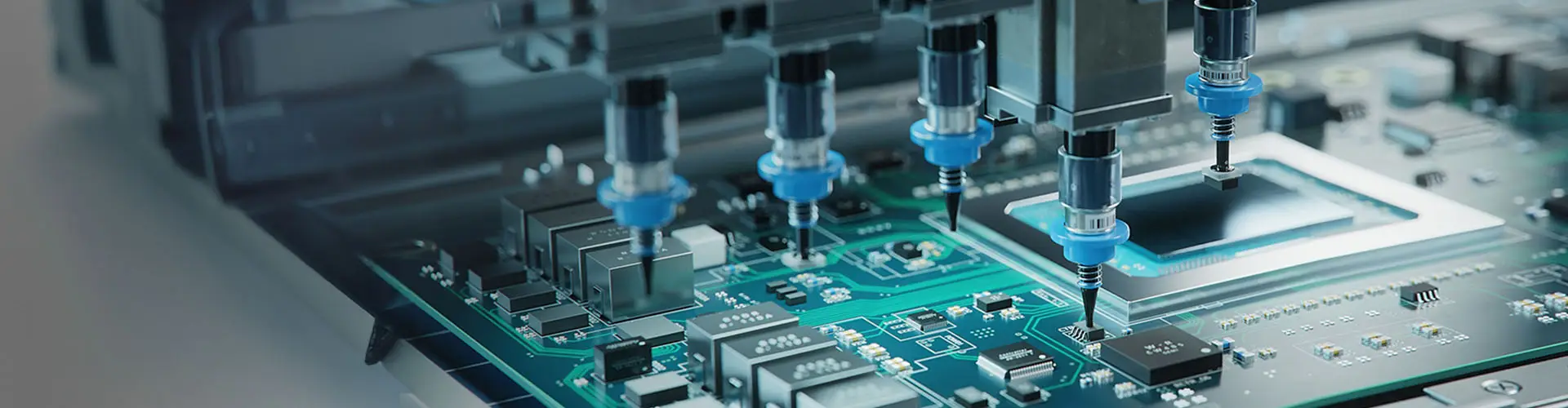

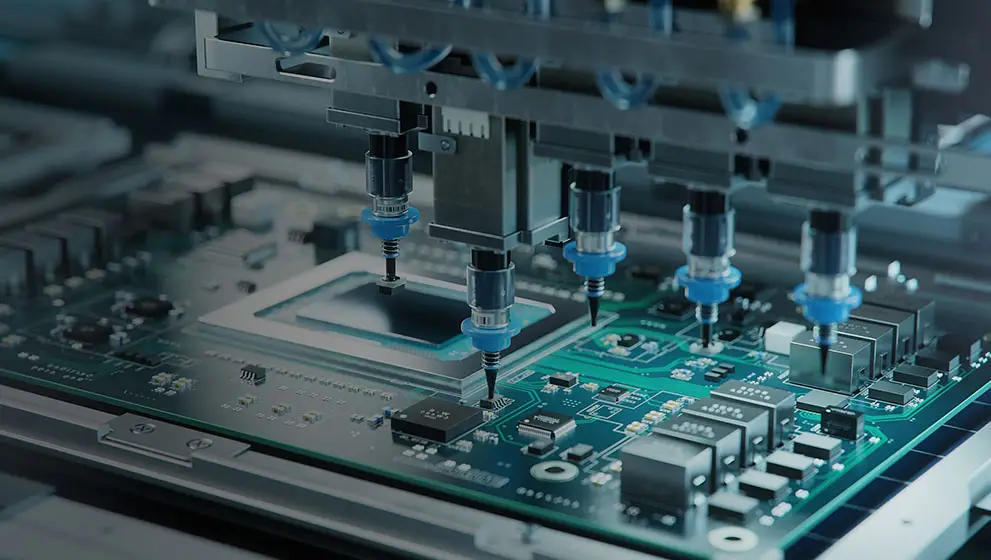

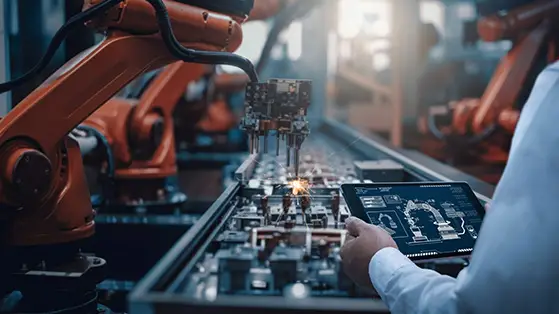

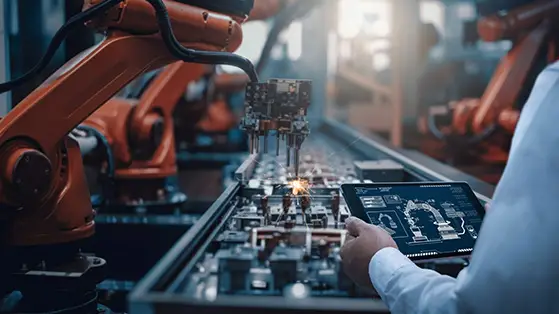

Five of the largest global EMS companies have a manufacturing presence in Singapore, providing holistic services from new product introduction (NPI) to final assembly.

6th

largest exporter of high-tech goods globally1.

18.5%

Manufacturing's contribution to Singapore’s GDP in 20252.

3,000+

A comprehensive ecosystem of precision engineering suppliers supporting a myriad of industries3.

Five of the largest global EMS companies have a manufacturing presence in Singapore, providing holistic services from new product introduction (NPI) to final assembly.

With over 3,000 precision engineering companies supplying end-to-end solutions across industries like semiconductors, medtech and aerospace.

Over 15,000 STEM graduates annually, ensuring a steady talent pipeline equipped for advanced manufacturing roles.

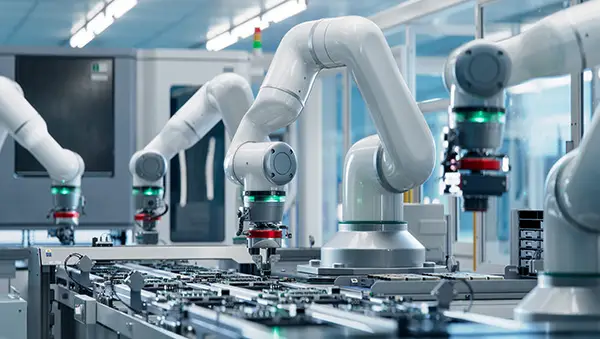

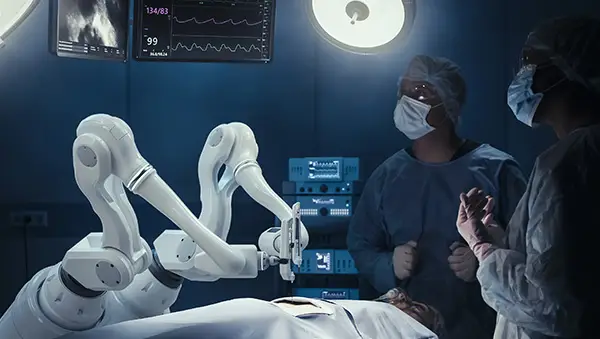

Singapore is a global hub for robotics innovation and R&D. With a strong focus on technological advancement and a supportive ecosystem, the nation is at the forefront of developing cutting-edge robotic solutions.

Together with the National Additive Manufacturing Innovation Centre, Singapore has built a robust ecosystem of equipment, materials, and testing solutions and is now home to a diverse mix of additive manufacturing companies.

National initiatives such as the Sectoral AI Centre of Excellence for Manufacturing (AIMfg) help Singapore achieve manufacturing excellence across industries.

Located in the heart of a $10 trillion Southeast Asian market, Singapore offers an ideal base to access and serve the region’s fast-growing economies.

Initiatives like the Southeast Asia Manufacturing Alliance help businesses diversify their supply chains across the region, enhancing stability and scalability.

With extensive free trade agreements and robust intellectual property laws, Singapore enables companies to optimise cross-border operations securely and efficiently.

The semiconductor industry in Singapore contributes to 10 per cent of global semiconductor output.

With the second highest robot density in the world and over S$450 million pledged to support robotics, Singapore is driving innovation and powering Southeast Asia’s future.

Makino Asia supports industrial transformation of its regional customers through its activities production and R&D at Jurong Innovation District.

Leverage Singapore’s innovation ecosystem, connectivity to key markets and skilled workforce to grow in this region.

The Industrial Postgraduate Programme supports companies in their efforts to build a pipeline of local R&D talent.

From digital transformation to innovation and sustainability, read about Singapore partnering businesses to building factories of the future.

Read morePartnerships in Singapore that have contributed to stronger supply chains, improved productivity and sustainability, and shorter time to market.

Read more

Referenceskeyboard_arrow_down