Deepening collaborations

Still, efforts to upgrade these SMEs continue.

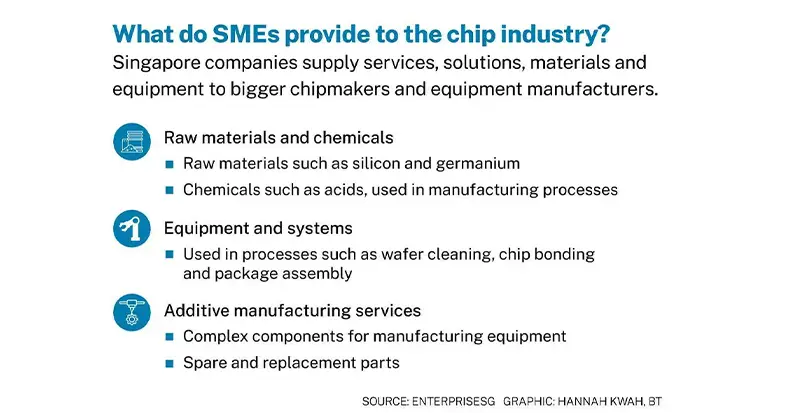

The government has shifted the focus of its aid for semiconductor-supporting players from productivity efforts to innovation and “capability building in higher-value activities”, noted Anne Ho, director for advanced manufacturing at Enterprise Singapore (EnterpriseSG).

MNCs can further spur this transformation. As semiconductor and equipment giants expand operations here, this “attracts more foreign suppliers and allows more local suppliers to grow their capacities and capabilities”, said an EDB spokesperson.

EDB wants to further catalyse partnerships between MNCs and local businesses, as well as build up local capabilities. The Partnerships for Capability Transformation scheme has been enhanced to support this, while national research institute A*STAR facilitates such tie-ups.

Said Ho: “Such collaborations not only enable larger companies to build more resilient relationships in the Singapore ecosystem, but also help our SMEs to benefit from the technical knowledge, resources and networks of their larger partners, to deepen their capabilities and expand their operations to more regional and global markets.”

Such initiatives by the government and trade associations help to increase MNCs’ awareness of local suppliers, said Bertrand Stoltz, STMicroelectronics executive vice president for finance, global business services and financial system, and Asia public affairs.

“We got to know ELH through SSIA’s introduction. We need more of these awareness and connectivity (efforts) on who are available in local SMEs that have the relevant technology that we need,” he said.

Working with local suppliers ensures that repairs can be done quickly, so factories have minimal downtime, said GlobalFoundries’ Tan. “Otherwise, if you need to wait for supplies and support from overseas, it will have a time lag in terms of flying in the parts.”

For SMEs, such collaborations open doors to more customers through further introductions and word of mouth, said ELH’s Si. Since its partnership with STMicroelectronics, the company’s chip business has grown to 15 to 20 per cent of overall revenue, up from one to five per cent before.

Fellow SMEs are also doing their part. Local startup Factorem connects global manufacturers to local suppliers on its online platform where suppliers list their services for manufacturers to choose, based on their needs.

Co-founder Alexandra Zhang said that a big part of the company’s early years was spent going door to door to make a case to local suppliers that there were opportunities in the global market. Forty-six per cent of its transactions involve international buyers.

“Once they see (the jobs that are out there), I feel... the picture speaks for itself,” she said. Suppliers are charged per transaction gained via the platform.

EnterpriseSG also helps SMEs access the foreign market by leading overseas trips and keeping tabs on developments that may bring new opportunities. For instance, EnterpriseSG and SSIA plan to take SMEs to India later this year.

With US firms increasingly diversifying and sourcing for Latin America-based suppliers in the nearshoring trend, some SMEs are also exploring Mexico as a potential market for expansion, said EnterpriseSG’s Ho.

By upgrading, SMEs can also improve their relationships with MNCs. Having specialised and higher-end capabilities can help SMEs become critical to an MNC’s supply chain, and thus retain that client.

SPETA’s Wong noted that semiconductor giants usually categorise suppliers in tiers based on their importance. “If you’re in tier three and tier four, you may be in a space where there are many others apart from you,” he said. In contrast, being a critical tier one supplier ensures a level of “stickiness” to the client.

Still, having capabilities may not be enough to secure a close relationship, he added. Big players often have an established pool of suppliers, so local enterprises will need to present a strong business case to be considered.