Nonetheless, the panellists agreed that long-term investments will eventually be realised.

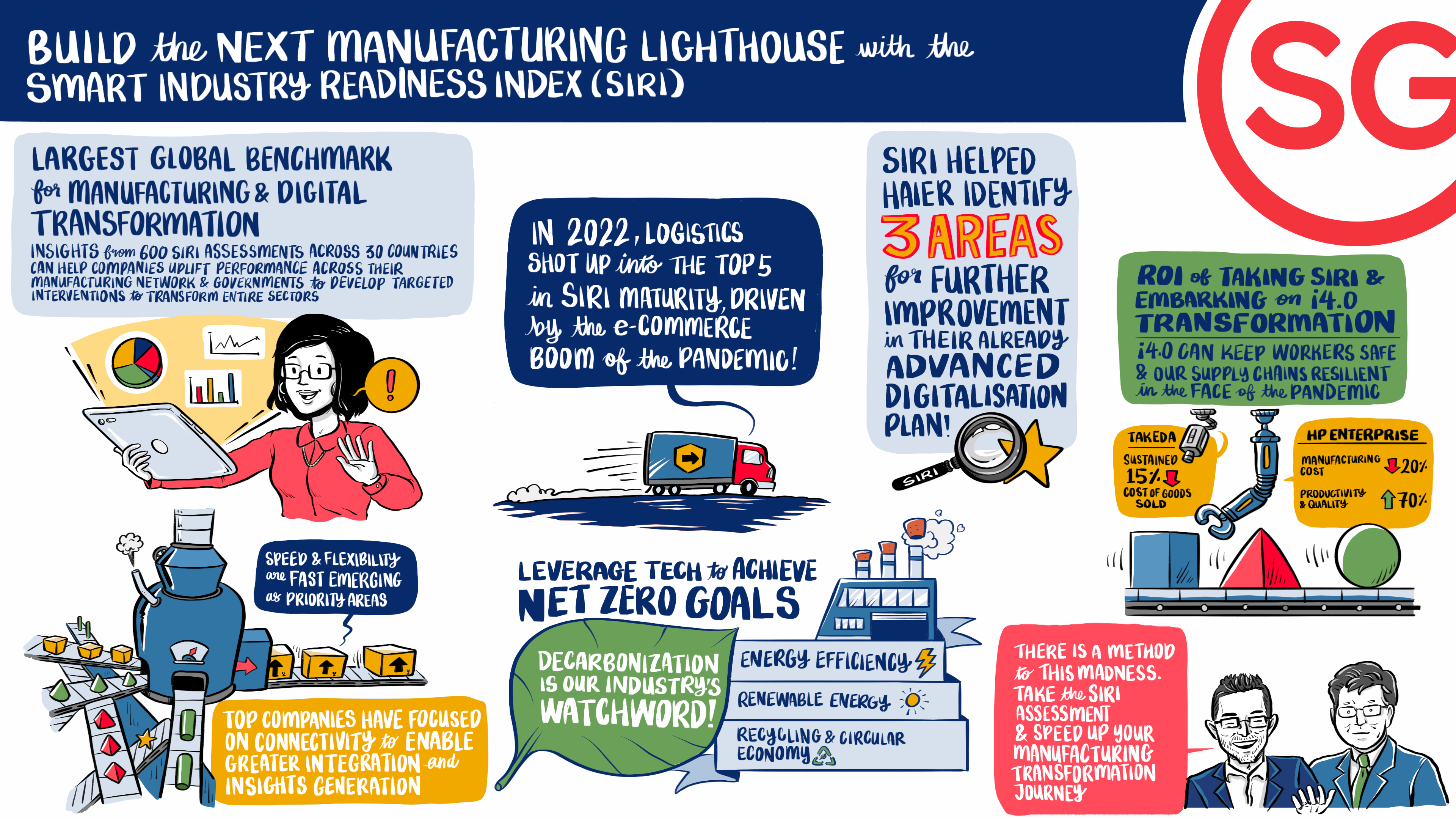

Vighnesh elaborated that Takeda’s investments in smart analytics and digital technologies has helped the company reduce the cost of goods and increase its yield.

“In terms of yield, our efficiency levels have increased more than 15 percent in terms of reducing the cost of goods,” he said.

HP’s Tian Chong shared his sentiments on ROI from two perspectives.

“From a qualitative viewpoint, digital transformation has made our supply chains more resilient, especially throughout the pandemic. We have taken advantage of the Industry 4.0 technologies we’ve deployed at our factories to not only improve performance and keep the supply lines running when labour was short when workers could not go to work; it was also to protect the health and safety of our employees,” he explained.

On the quantitative front, Tian Chong added that the implementation of the SIRI framework has helped his business reduce its manufacturing costs by 20 percent and improved productivity and quality by 70 percent.

“These are huge improvements and these have resulted in HP Singapore being part of the Global Lighthouse Network, which we’re very proud of,” he said, referring to the WEF’s global community of manufacturers that leverage Industry 4.0 technologies to successfully transform factories, value chains and business models.

Setting the stage for a successful journey

All speakers concurred that industrial transformation efforts must be complemented by other key factors.