At the farms, I noticed that each Holstein cow – one of the world's highest milk producers – has a different set of patterns. It is like their thumbprint. This was something new to me. They also said each cow drinks 150 litres of water a day because they are always thirsty.

I have also travelled to China to source tea leaves. There are many types of tea, like pu’er or tie guan yin. A farmer told me an important fact: Generally, all tea types come from the same species of plant. The difference is in how they harvest and how they process the tea leaves.

When we launched yuzu juice in Singapore, the benchmark in the market was Japanese yuzu. So we bought yuzu juice concentrate from Japan and developed it from there. Even for apples, there are thousands of varieties that have different tastes.

To develop the best drink, how do we find the benchmark for it? For teh tarik specifically, I went to mamak stalls in Malaysia to find those that serve good ones. For me, it is too subjective. So we leveraged our supplier partner who brings advanced sensory tools to identify the aroma and flavour of the drink.

To make it easier to describe the aroma or taste among ourselves, including the sales and marketing teams, we must speak the same sensory language, also termed as sensory lexicon. What is considered sweet or creamy? The definition of sweet for many people, as well as in different countries, can be very different.

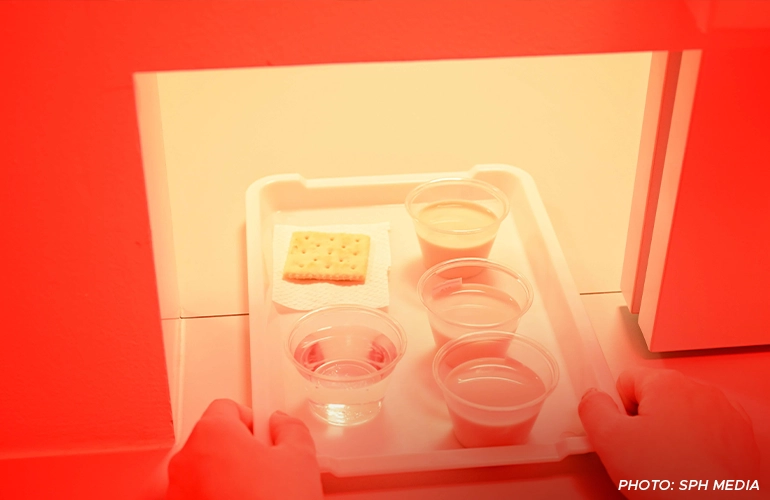

Staff who are interested in joining our sensory evaluations – conducted in sensory booths – will be required to undergo training and a basic screening test before they can qualify as a panellist. Some protocols have to be observed, such as making sure samples are prepared hygienically. Also, no discussions are allowed, this is to prevent personal biases from influencing the participants’ decisions.