In the Chin Bee area in Jurong, a lab has been cooking up pork dumplings, wantons and bao. No pigs were killed in the making of these Asian bites, however, as cultured pig cells were used instead.

Alternative protein start-up Ants Innovate is betting its minced pork, chicken and beef products, made from a blend of in-house plant-based proteins, fats and animal cells, will find a meat-loving audience in time.

Not only does the blended pork retain the flavour and aroma of meat, Ants Innovate also expects it to be cheaper than pure cell-based meat, since fewer animal cells are used, making it easier to bring the novel food to market, said the start-up's Co-Founder Ong Shujian.

“Consumers care about taste, nutrition and price when it comes to alternative proteins,” he said. “In a few years, we believe cultivated meats will deliver much higher quality flavour, texture, appearance and nutrition than any current plant-based meat.”

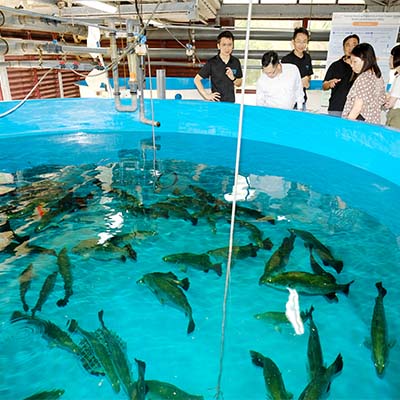

The research by Ants Innovate is part of a race to produce more climate-friendly and nutritious foods that use far less resources to feed nearly 10 billion people by 2050. And many of the solutions lie in growing animal cells in bioreactors, making plant-based meats and unlocking new proteins through fermentation, alongside high-tech urban farming and aquaculture.

Traditional agriculture both causes, and is hurt by, climate change.