One-stop solution

Back in 2009, Blue Aqua only had farm care products, namely minerals and probiotics for water treatment purposes, under its brand. Over the years, however, the company noticed changing trends and consumer demands, and diversified its business accordingly.

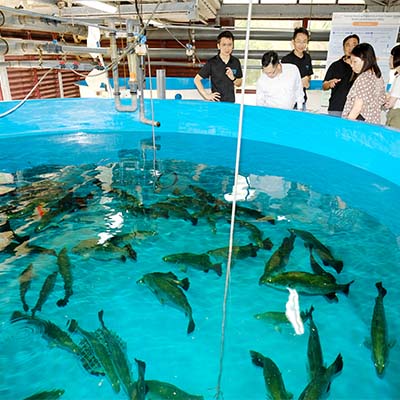

Blue Aqua has also grown its presence quickly across different markets, and today has 5 farms across Singapore, Indonesia and Oman. Over the past decade, the company has established interests in different areas; such as consulting services and turnkey solutions for farms, and lab capabilities to detect farm diseases.

Of the 3 farms it runs in Singapore, the company’s shrimp hatchery has 5 species of shrimp, and a capacity of 100 million post-larvae annually.

Meanwhile, Blue Aqua’s cage farm for fish here is able to produce 300 tonnes of food fish per year, while the farm for fish and shrimp can produce 600 tonnes of food fish and 120 tonnes of shrimp per year.

The company also has a retail brand that sells fish and shrimp to grocery stores and restaurants around Singapore.

Today, Blue Aqua has a “closed-loop” aquaculture ecosystem. The company collects food waste from airport services provider Dubai National Air Travel Agency (dnata). The food waste is then processed and fed to insects. These insects are then combined with algae to form a protein that can be used in place of fishmeal. This protein is then supplied to fish and shrimp farms.

Blue Aqua’s end-to-end presence means the company is able to track processes across the chain of operations. This has become more critical as consumers have become more informed.

Shishehchian recalls how in the past, consumers would just accept products without questioning where they came from. Today, consumers are paying more attention to where their food is coming from, the amount or types of chemicals used, as well as social factors such as animal welfare or child labour at farms.

As things stand today, he believes the farming industry is not yet ready to answer all these questions, but the use of big data and analytics could go a long way in helping farmers better understand the processes in farms, which would put them in a better position to address such concerns from consumers.

Demand has also been strong, Shishehchian added. He recalls a significant pick-up in demand in Singapore when the Jurong Fishery Port was closed due to the Covid-19 cluster there. Fish and shrimp were sold out quickly, and Blue Aqua struggled to keep up with demand.

He expects the need for sustainable aquaculture will grow alongside the global population. In his view, companies like Blue Aqua will have to do their part to ensure that enough resources are available for future generations – especially since available livestock is on the decline.

Easier and more efficient

While farming is one of the oldest trades, Shishehchian is quick to stress the importance of using big data and technology to improve processes. Blue Aqua has already begun this journey, but there are still several “grey areas” for the industry at large, he said, adding that there is an urgent need for companies to play catch up.